FACC collaborates to reduce weight in aerospace

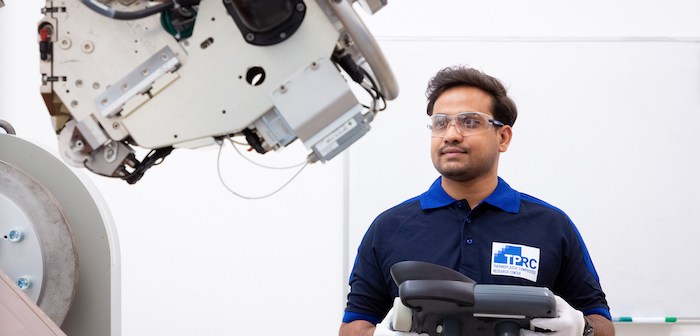

As aviation is put under increasing pressure to reduce its emissions, OEMs and suppliers are playing an important role in developing new lightweight and resilient materials, and sustainable production techniques. FACC is further developing its role through joining the ThermoPlastic composites Research Center (TPRC), an international research centre and network, based in Enschede, Netherlands, which is investigating possible further developments and applications of new materials.

FACC joins major international aerospace companies at TPRC, including Boeing, Spirit AeroSystems, Collins Aerospace and GKN Aerospace. FACC will collaborate with these technology companies, with a focus on conducting research into the further development of lightweight materials, so-called thermoplastic fibre composites. These composites are particularly attractive for the aerospace industry as they are very lightweight and are fully recyclable.

“The short manufacturing time of the components is of particular interest to us,” explained Robert Machtlinger, CEO of FACC AG. “This enables costs to be cut and energy consumption of the processes to be reduced, which confers a key competitive advantage, particularly in the dynamic field of urban air mobility. Possible solutions range from support and control surfaces to cabin components.”

“Resilience, lower weight, processability, recyclability and cost effectiveness: the demands placed on materials for the construction of aircraft and drones are extremely high,” added René Adam, director of research and technology at FACC. “The materials that are currently being researched together with international partners offer enormous potential in this regard. Manufacturing by means of thermoplastic fibre composites has now become one of the core elements of materials and process research in the aerospace sector.”

From TPRC’s side, the centre is pleased with the addition of FACC’s expertise. “FACC’s ambitions regarding the use of thermoplastic composites fit seamlessly into the research roadmap of the TPRC,” said Sebastiaan Wijskamp, technical director of the TPRC.

“Our knowledge of the fundamentals of thermoplastic composites will definitely speed up the further use of thermoplastic technologies at FACC, while we, in turn, stand to greatly benefit from FACC’s leadership and guidance as an industrial partner with a clear vision for the commercial application of thermoplastic composites,” added Wijskamp.