Airbus unveils new A350 performance and Airspace cabin enhancements

Below, Airbus Corporate Communications’ Martin Fendt explains the benefits of the aircraft manufacturer’s exciting new enhancements for its A350 aircraft.

The best widebody gets even better – A350 introduces new performance and Airspace cabin enhancements, benefitting passengers, crew, and airlines.

Reinforcing the A350 Family’s position as the most sustainable large widebody today, with lower structural weight, enhanced performance, maximum versatility and more cabin space, choice and flexibility for all business models

Airbus is introducing new A350 performance gains combined with various cabin enhancements for airlines and their passengers. This comes with a new product evolution standard now being delivered to airline customers. The performance improvements include weight savings, improved take-off performance, and increased Maximum Take-Off Weight (MTOW) capability. The Airspace cabin improvements provide more space, choice and flexibility, covering a wider cross-section in the revenue passenger areas, more space at both the front and rear of the aircraft for new larger galleys, a new flight-crew rest compartment in the upper crown area, and a new large forward lavatory. The new standard also includes the option for the latest third-generation of electro-dimmable windows.

1. A350 PERFORMANCE IMPROVEMENTS

Structural weight reduction – for lower CO2 emissions and greater productivity

When compared with the A350s in service today, the new standard brings a significant overall weight reduction. Both the A350-900 and larger A350-1000 benefit from these improvements – which account for up to 1.2 metric tonnes of weight reduction. Airbus achieved this by optimising systems, structures and installations on various areas of the aircraft. These included the electrical system installation with further optimisation in the crown with new cable concepts; cabin systems optimisation – such as a new single water tank, a new waste tank and lighter floor panel heating. In the mechanical system installation Airbus has introduced new composite ducts for a more optimised air distribution. There are also new nacelle and pylon structural weight-saving optimisations.

The A350 Programme has also taken the opportunity to increase the use of advanced materials such as carbon fibre to further reduce weight. For example in the wing structure we further optimised upper and lower wing covers, the landing gear support structure, and in the fuselage structure there is additional use of CFRP in the door surrounds.

Improved hot & high take-off performance for greater operational flexibility

These latest A350s will also benefit from an enhanced take-off performance especially when operating out of challenging airports (high altitude, short runways, hot weather etc.). To this end Airbus has introduced software evolutions which regulate the slat and flap positions, and has also implemented a faster landing gear retraction cycle – conferring greater obstacle clearance and reduced aerodynamic drag.

With these changes, the A350-900 could, on average, benefit from 3.5 additional tonnes of available take-off weight (e.g. for extra fuel and/or payload uplift) from a limiting runway, while the larger A350-1000 benefits from an approximate 2.5 tonne improvement. At some airports the potential take-off weight uplift gains could be improved by more than six tonnes (ie. at La Reunion and Mumbai), or by more than four extra tonnes (at Phoenix or Dublin). Overall, take-off weight improvements for the newest A350s would occur at around 50 airports currently operated by widebody aircraft. Airbus has also increased MTOW capabilities (now up to 283t for the A350-900 and 319t for the A350-1000) allowing them to maintain their respective maximum range capabilities, beyond 8,000nm, while carrying greater revenue payload than before.

2. A350 AIRSPACE CABIN INNOVATIONS

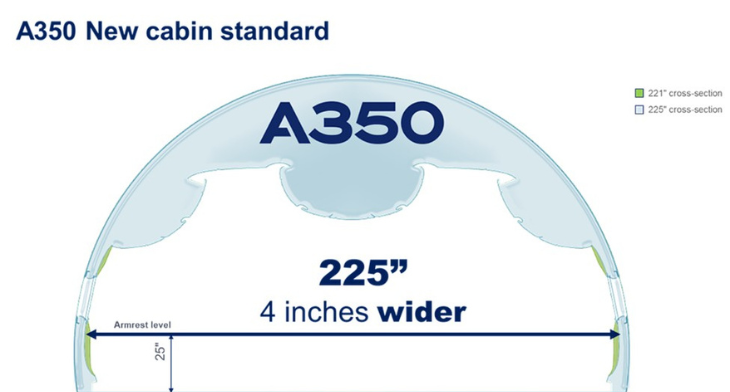

Wider Airspace cabin for further class-differentiation possibilities, flexibility and increased space

One of the most significant A350 cabin improvements is the additional cabin volume thanks to four inches of cabin width, bringing it to 225 inches. This extra room comes from re-sculpting the sidewalls which releases two-inches on each side along the cylindrical constant section.

Since the extra cabin width benefits all classes of passenger seating, the extra space can go towards widening the aisles, the armrests, seat-pan in between the armrests, the centre console in Premium Economy – or a combination of these. Moreover, while the A350 today already offers a 10-abreast option for airlines that need a high-density layout, the extra width in the latest A350 standard transforms the passenger comfort of previous 3-4-3 arrangement by now accommodating the full 17-inch wide industry standard economy seats – already used by many mainline carriers for their passengers.

Notably, compared with a nine-abreast Economy Class, the new 10-abreast offering could enable airlines to accommodate approximately 30 additional seats, in a typical three-class layout on their new A350-900s and the A350-1000s.

The wider cabin also allows for further class-differentiation and revenue-generation possibilities. For example, the original economy seats in a 3-3-3 arrangement – formerly 18-inch seats – now can become even wider – 18.7 inches – verging into ‘economy-plus’.

Meanwhile the premium economy cabin can grow to offer 19 inch seats with a five inch centre console and an 18 inch aisle.

Designed-in flexibility for growth to 10-abreast seating

Flexibility is designed-in to the new cabin, so that airlines who initially select a nine-abreast 3-3-3 economy section could easily upgrade it in the future to the new 10-abreast layout. This flexibility is made possible the same seat rails, tracks and IFE interfaces will fit either nine or 10 abreast seating – without needing to change the floor attachment interfaces when changing the seats from one to the other.

Flexibility also applies to the supporting floor panels of the original A350 design – which were already sized for future higher seat densities, such as with the new 10-abreast option. Likewise, the aircraft’s plentiful air-conditioning flow capacity is matched for extra passengers, so no change was needed here either.

Retaining all the benefits of the original A350 Airspace cabin

In parallel, uprated insulation in the new sidewalls ensure that the acoustic and thermal insulation properties remain at the same industry-leading levels as before – and therefore the A350 remains the quietest aircraft in its category. The A350 is also renowned for having near-vertical sidewalls – thanks in part to its carbon-fibre fuselage construction which permits a non-circular fuselage cross-section. Passengers will therefore be pleased that the enlarged cabin cross-section retains this vertical sidewall feature, in particular so that the extra width is available at hip, shoulder and also at head level. Another benefit of the CFRP fuselage construction is the lower (6,000ft) cabin altitude pressure combined with improved humidity levels during cruise – leading to less overall passenger fatigue.

Longer cabin – larger galley & lavatory areas for improved cabin crew workspace and enhanced in-flight passenger service

In addition to the four-inch cabin width increase, Airbus engineers have also reclaimed 35 more inches of cabin length. This has been achieved by slightly shifting forwards the cockpit wall and optimising monument arrangements, while at the back of the aircraft, behind the last set of doors, the rear pressure bulkhead (RPB) has been repositioned by one frame rearwards – thus making extra space for an even larger rear galley area.

The resulting new redesigned monuments provide additional flexibility and catering capacity for operators, as well as improved working areas for flight crews. For example, the increased monument floor space available in the front-left area (forward Door1L) allows for up to four trolleys (previously three). Alternatively, a 50-inch wide PRM-capable, premium lavatory can now be installed there, sufficiently wide and also with a ramp for direct wheelchair access. It also includes an additional call button, handles plus other PRM-friendly features.

Meanwhile, just opposite, on the right-hand-side (just forward of Door1R) the large galley offers useful worktop space, more space for galley-inserts (GAINS). This was achieved not only by moving the cockpit wall, but also by relocating the staircase to the Flight Crew Rest Compartment (FCRC) – previously in the front-right galley area – to the other side of the adjacent centre galley, aft of Doors1. Overall, the changes to the forward area galleys allow for up to three more trolleys than before, including the optional crew-rest.

When it comes to the rear galley area, the A350 cabin now brings the possibility of eXtra Large (“XL”) galleys that allow for up to six additional trolleys with an increase in floor surface area as well as effective working area for crews. Once again, flexibility is part of the A350, which is enhanced thanks to the extra space resulting from moving the RPB further back. The result is that it is now possible to offer airlines a new “V-shape XL Galley”, or an “ICE XL Galley” (ICE = Increased Cabin Efficiency). The latter can incorporate two lavatories – one either side (as did the previous ICE Galley), thus freeing-up extra space in the revenue passenger cabin in front of Doors4.

Electro-dimmable windows – blocks 99.999% of light, reduces weight and is easy to maintain

Now that electro-dimmable window (EDW) technology has matured, Airbus is pleased to offer this solution to its customers of the newest version of the A350 Family now being delivered. Compared with previous designs, the latest generation of EDWs, developed by Gentex, darken twice as fast and become 100 times darker than the original version. In addition, they can now effectively block more than 99.999% of visible light as well as the infra-red energy from the sun (which also helps to keep the cabin interior cooler and thus reduce the load on the air-conditioning system). STARLUX Airlines, headquartered in Taipei, is the first operator to select these devices for its newly-delivered A350 aircraft.

Gentex supplies the latest 3rd-generation EDWs for the A350

The new EDWs also provide more comfort to passengers by allowing individual dimming of their windows while still looking outside if they wish. The windows also bring advantages for maintenance crews since they can be easily and quickly unclipped from the window bezels using a special tool (and without having to remove any seat or sidewall panels) and immediately swapped-out with a serviced replacement insert – which also makes for a fast turnaround.

3. SUMMARY

The new standard of A350s include a wide spectrum of value-adding product evolutions. Moreover this approach is the latest example of Airbus’ policy of continuously driving innovation to improve its aircraft products, based on its customer needs. The A350 Family, which was already the world’s most advanced and efficient new widebody, provides airline customers with increased performance, efficiency and revenue-generating possibilities. Furthermore, the A350’s Airspace cabin now offers even more space and choice for airlines to create a superior in-flight service and experience for their passengers.