The High-Speed Logistics of Formula One: Challenges, Innovations, and Sustainability

Formula One is known not only for its speed, skill, and strategy but also for being a colossal logistical operation that involves the swift movement of tons of equipment, cars, and personnel across the globe within a matter of days. How do the teams manage this intricate and costly task, and what challenges do they face in the 2023 and 2024 season?

Formula One is often referred to as the “pinnacle of motorsport,” showcasing cutting-edge and innovative racing technology. Each team possesses two cars and approximately 50 tons of equipment, including spare parts, tools, fuel, oil, tires, broadcast equipment, and entertainment accessories. These items are indispensable for the teams to participate in the 22 races spanning five continents over nine months.

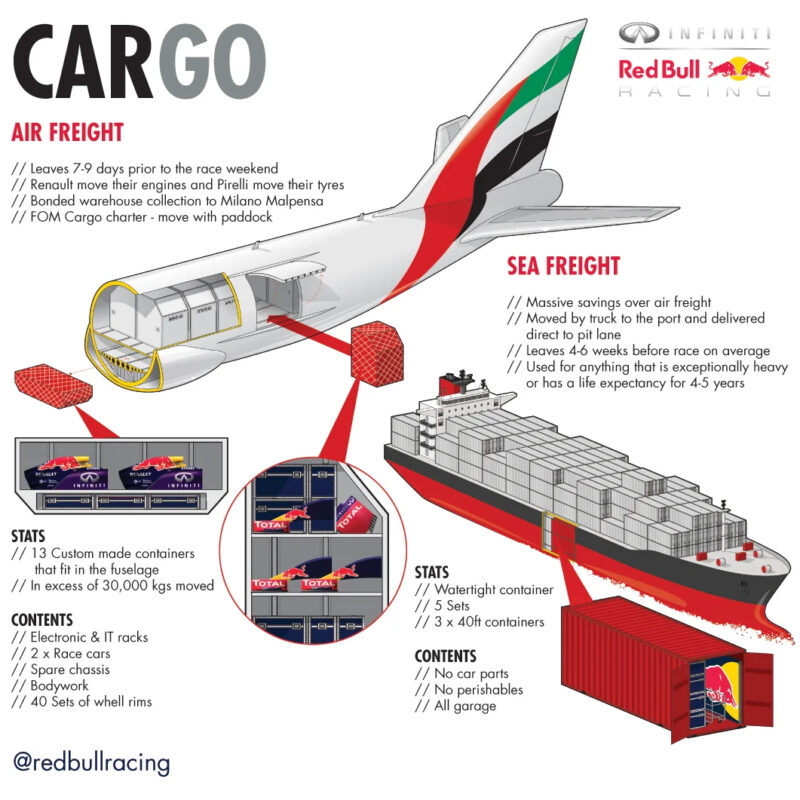

Teams employ a combination of three modes of transportation: road, air, and sea, depending on the race’s location and schedule. For European races, which constitute roughly half of the season, teams primarily rely on road transport. They use liveried articulated lorries capable of carrying up to 40 tons each. These trucks double as mobile workshops and hospitality units for the teams.

In the case of overseas races like Bahrain, Australia, Brazil, and Japan, teams turn to air freight to transport their cars and equipment. Each team has a dedicated cargo plane, typically a Boeing 747, with a capacity of up to 120 tons of freight. These planes are operated by DHL, Formula One’s official logistics partner, which deploys a team of 35 specialists to manage the transportation, setup, breakdown, and packing of the cargo at each race. DHL also provides sea freight services for less time-sensitive equipment, such as spare engines, gearboxes, and chassis, which are shipped in containers several weeks ahead of time.

Formula One logistics are not just demanding but also expensive. Estimates suggest that each team spends approximately $10 million per season on transportation, accounting for roughly 10% of their total budget. Costs vary based on factors like distance, mode of transport, frequency, and the customs duties, taxes, and insurance fees applicable in various countries.

Additionally, Formula One logistics are subject to numerous uncertainties and risks, including weather conditions, traffic, technical glitches, accidents, strikes, political instability, and health crises. For instance, in 2021, the Haas team missed the initial round of pre-season testing in Bahrain due to a delay in their cargo plane in Istanbul, attributed to technical issues. The COVID-19 pandemic in 2020 resulted in the cancellation or postponement of several races, necessitating strict health and safety protocols for teams, such as personnel reduction, regular testing, and isolation in secure bubbles.

Formula One logistics are evolving to align with sustainability and environmental goals, aiming for net-zero carbon emissions by 2030. Measures being taken by teams and DHL to reduce their environmental footprint include the use of biofuels, electric vehicles, renewable energy sources, carbon offsetting, and recycling. DHL employs data analytics and optimization tools to plan the most efficient routes and schedules for cargo flights and trucks.

Formula One stands as a sport that continuously pushes the boundaries of technology, performance, and logistics. Teams face the ongoing challenge of swiftly moving their cars and equipment from one race to the next, ensuring their readiness for competition at the highest level. The logistics of Formula One constitute a vital and intriguing facet of the sport, often overlooked by fans but deserving of recognition and appreciation.

Sources: AirGuide Business airguide.info, bing.com, DHL